Especificações resumidas

-

Process temperature

Max. 150 °C (302 °F)

-

Process pressure

Max. 10 bar (145 psi)

Campo de aplicação

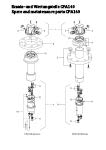

The Dipfit CPA140 immersion assembly is designed for all demanding applications where aggressive media are involved. With its flange connection, Dipfit is installed safely in the process and offers space for three sensors. Its bayonet lock offers you easy sensor installation even in sticky media or media containing solid particles, thus saving time for maintenance and recalibration.

Dipfit CPA140 is intended to be used in closed tanks in:

Chemical industry

Petrochemical industry

Life sciences

Power plants and waste incinerating plants

Extractive metallurgy and metal processing

It is suitable for use with pressures of up to 10 bar (stainless steel) or 6 bar (PVDF).

Benefícios

Simple installation and removal of the electrode holder thanks to bayonet lock

Flexible connection to the process by means of various flanges (DIN, ANSI, JIS)

Less condensation due to a Goretex filter

Reduces installation effort by providing 3 mounting positions for 120 mm sensors plus a cleaning unit

-

Produtos com tecnologia de ponta

- Altamente funcional e prático

Excelência técnica

Simplicidade

-

Produtos especializados

- Desenvolvidos para aplicações exigentes

Excelência técnica

Simplicidade

Variável

| Versões FLEX | Excelência técnica | Simplicidade |

|---|---|---|

Versão Fundamental Atende suas necessidades básicas de medição |

Excelência técnica

|

Simplicidade

|

Versão Lean Lida com seus principais processos facilmente |

Excelência técnica

|

Simplicidade

|

Seleção Extended Otimiza seus processos com tecnologias inovadoras |

Excelência técnica

|

Simplicidade

|

Versão Xpert Controla suas aplicações mais difíceis |

Excelência técnica

|

Simplicidade

Variável |

-

-

Informações Técnicas (TI)

Dipfit CPA140 Informações técnicas

Conjunto de imersão com conexão flange para processos muito difíceis

EN PT 31/08/201801/09/1998Idioma:

Português

Versão:

31/08/2018

Tamanho do arquivo:

581.7 KB

Nome do arquivo:

TI00178CPT_1318.pdf

-

-

-

Instruções de Operação (BA)

Dipfit CPA140 Instruções de operação

Conjunto de imersão para pH ou sensores ORP

EN PT 31/08/201801/09/1998Idioma:

Português

Versão:

31/08/2018

Tamanho do arquivo:

1.3 MB

Nome do arquivo:

BA00178CPT_1318.pdf

-

-

-

Folheto de Competência (CP)

pH measurement in industrial processes

Selection and engineering guide for different industries and

applicationsIdioma:

Inglês

Versão:

02/12/2021

Tamanho do arquivo:

3.2 MB

Nome do arquivo:

CP00010CEN_1621_pH selection guide_2021.pdf

-

-

-

Folheto de Competência (CP)

産業プロセスにおけるpH測定

さまざまな産業およびアプリケーション向けのpH測定セレクションガイド

Idioma:

Japonês

Versão:

08/02/2024

Tamanho do arquivo:

5.8 MB

Nome do arquivo:

pH selection guide_CP00010C.pdf

-

-

-

Folheto de Competência (CP)

pH-Messung in Industrieprozessen

Auswahl- und Engineering-Hilfe für verschiedene Industriebranchen und

ApplikationenIdioma:

Alemão

Versão:

01/12/2021

Tamanho do arquivo:

3.3 MB

Nome do arquivo:

CP00010CDE_1621_pH Auswahlhilfe_2021.pdf

-

-

-

Estudo de Caso (CS)

Process automation worth its weight in gold

Memosens pH sensors improve processes at Agnico Eagle

Idioma:

Inglês

Versão:

01/07/2016

Tamanho do arquivo:

1.5 MB

Nome do arquivo:

CS01496CEN_0116_Agnico Eagle goldmine.pdf

-

-

-

Estudo de Caso (CS)

Prozessautomatisierung, die Gold wert ist

Memosens pH-Sensoren verbessernProzesse bei Agnico Eagle

Idioma:

Alemão

Versão:

01/07/2016

Tamanho do arquivo:

1.5 MB

Nome do arquivo:

CS01496CDE_0116_Agnico Eagle Goldmine.pdf

-

-

-

Estudo de Caso (CS)

L’automatisation des process vaut son pesant d’or

Memosens Les sondes de pH améliorent les process chez Agnico Eagle

Idioma:

French

Versão:

01/07/2016

Tamanho do arquivo:

673.1 KB

Nome do arquivo:

CS01496CFR-0216-Agnico Eagle.pdf

-

-

-

Declaração do Fabricante

Product family: DipFit P

Product root: CPA140-

Declaration number: HE_01135_01.19

Manufacturer specification: PEDEN PT 28/03/2019Idioma:

Inglês

Versão:

28/03/2019

Tamanho do arquivo:

291.7 KB

Nome do arquivo:

HE_01135_01.19_PED_CPA140-PVDF.pdf

-

-

-

Declaração do Fabricante

Product family: DipFit P

Product root: CPA140-

Declaration number: HE_01136_01.19

Manufacturer specification: PEDEN PT 28/03/2019Idioma:

Inglês

Versão:

28/03/2019

Tamanho do arquivo:

289.3 KB

Nome do arquivo:

HE_01136_01.19_PED_CPA140-316L.pdf

-